- Successful consultations in special cases specializing in fine coaxial cable processing.

- Reliable Technology even for Medical System Related Processes

- Process technology straight from assembly stage up to advanced operations of harness processes

- Bringing confidence in high performance products that causes characteristic high impedance

coaxial

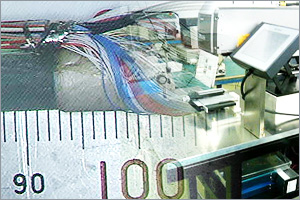

Non-contact laser processes

The processing that doesn’t damage a shield and an internal conductor is

achieved by the laser use.

|

|

Non-contact stripping process for wire (WIRE) using a laser

- Processes for non-contact cutting of only the metallic guide element film

- Stage processes involving two of the aforementioned items

- Non-contact coating processes for normal wires

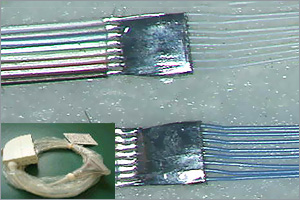

Soldering

The solder process will be authorized by a solder expert.

Such an authorization system within the company promises reliable technologies.

Fine pitch soldering is possible The solder used is lead free Examples: Consultation is available for miniaturization of medical scopes or other products, such as #48 wire round solder, 2 layer solder with 240 core and the like.